A few things to start off today's post before we get down to business. Over the last week, I have been very busy, making preparations to move from Calgary to Edmonton, Alberta. Henceforth, I have had little time over the past week to blog. Over this week, I should have plenty of time to dedicate to The Industrial Athlete, partly to help make up for lost time. Next weekend though, I will be moving most of my stuff up to my new place in Edmonton, so disruptions in posting may occur again.

Not only did last Friday's post mark the first case study to be examined on this blog, it also marked the occasion of The Industrial Athlete's first commenter. Congratulations SkookumJoe, you have just become a trivia question (i.e. first commenter)!

Staying with the comment that Joe made, he summed up one of the top problems that plague our hypothetical retail stock room...

Problem #1 -- Too much stock

This stock room has too much stock. Rows upon rows of goods that are out of season, or are present in quantities that surpass the "pull" from the consumer. This overstocking problem leads to crowded hallways, making navigation difficult. It causes goods and other non-sale items to be placed on the floor due to lack of space, increasing the risk of tripping and damage to the goods that are on the floor. It also leads to goods that are placed at a height that requires the worker to perform work above their shoulders and to use ladders, increasing muscular fatigue and retrieval time.

The solution to this problem would involve scheduling a lean intervention, putting into place a just-in-time delivery system for goods as they are needed. Goods should be acquired in quantities that address the consumer need for them (e.g. middle shoe sizes should be ordered in greater quantities than small or big shoe sizes) so that the store will not be caught short of the product that the consumer is seeking. Doing this would free up space in the stock room, allowing for easier movement within the area, and easier access to products that would otherwise be on higher shelves.

Problem #2 -- The ladders are few in number, and very heavy

For work that does require a ladder, getting access to one is difficult in our stock room. There are only a few ladders that are in the stock room, some of which are frequently taken by store staff to areas on the floor. The end result often leaves the staff in the stock room with the ladders that are much too high or heavy for practical use. This causes the staff to "climb" the shelves to access the stock needed, or to a dangerous attempt to move the heavy ladder into place.

Acquiring more lightweight ladders would be the step taken in this case. More importantly, a policy should be drawn up to restrict certain ladders to the stock room, while allocating others to the floor. Painting a stripe on the stock ladders would help define a stock ladder from a floor ladder. The heavy ladders should be replaced with stair ladders that have locking wheels that are easy to engage and disengage, accomplishing both ease of movement along with a higher height.

Problem #3 -- Manual material handling of heavy pieces of stock

When retrieving goods from the stock room, some pieces may exceed limits beyond what the worker's body can handle. Improper lifting techniques may be used, increasing stress on the lower back and other body structures. Pieces may be lifted and carried off the stock shelves without assistance, for reasons of self-determination or the activity level of the store. Finally, heavy objects may be located higher than they ought to be located, leading to increased physiological stress on the worker in question.

By using the NIOSH equation, common lifts can be analysed to see if they are safe to perform, given the parameters of the lift itself. If the lifting index is below 1, the lift can be considered to be relatively safe. Between 1 and 3, the lift is considered to be risky, and should be examined ASAP. Above 3, the lift poses a severe risk, and should be examined immeadiately. Proper lifting technique should be taught to workers (keep the load as close to the body as possible, bend with the knees, square up to the load instead of lifting it from an angle, etc), and mechanical assistance or help from another worker should be enlisted if the load exceeds safe lifting limits. If the load is within "safe limits", but the worker feels uncomfortable doing the lift, assistance should be sought before initating the lift. Finally, position heavier items on lower shelves (between 28" to 35" off the standing surface) so that retrieval is optimized, avoiding back bending or overhead reaching. In general, all retrieval of stock should take place between the knees and the shoulders to minimize physical stress on the body.

Problem #4 -- The carts

The carts provided are non-height adjustable, and one of the carts is a cheap box cart, fitted only with a rope for a handle. When unloading stock onto the sales floor, the worker often has to bend over at the back to retrieve items at the bottom of the boxes, causing increased stress to the lower back structures. The rope on the box cart makes it hard to steer, causing frustration and lost time, especially when the cart runs into displays, necessitating pauses to fix the disturbance left by the collision.

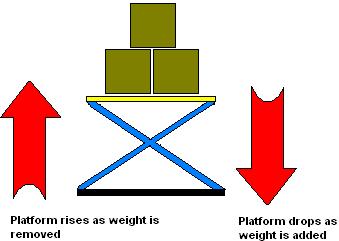

Acquiring adjustable height carts will allow the worker will retrieve stock from the cart at an acceptable working weight (between 33" and 38" off the standing surface). If the employer has more money to spare, a cart with an angle-adjustable surface should be considered, which will keep the stock closer to the worker in addition to maintaining a proper retrieval height. Alternatively, look into acquiring a load-levelling cart. They automatically adjust the cart height as stock is removed from the cart, eliminating the need for the worker to re-adjust the height themselves as they go.

Problem #5 -- Lack of visibility at the stock room doors

Finally, the stock room doors often are opened without warning, often striking unsuspecting workers on the other side. This has the potential to injure an employee's hand/head, not to mention scaring the wits out of them!

Putting a glass window will allow parties on both sides to know if anyone is approaching on the other side. Alternatively, a motion sensor could be placed near the doors, alerting workers on the other side to know when another worker is approaching, through an audio alarm. Also, a policy should be instituted where all workers opening stock room doors must open them slowly, allowing anyone on the other side to notice before placing themselves in harm's way.