Continuing on with our series of posts dedicated to eliminating non-neutral postures from your workplace, today the wrist gets our special treatment. Famous for being the structure of the body (next to the back) that sprung ergonomics to mainstream recognition (think Carpal Tunnel Syndrome!), and you'll see why it's vital to ensure that this area of the body is subjected to as little stress as possible.

There are 3 major positions that the wrist enters into awkward alignments:

1) Wrist Flexion (wrist "down-bending")

2) Wrist Extension (wrist "up-bending")

3) Wrist Deviation (wrist "side-bending")

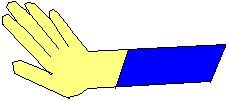

WRIST FLEXION

Problem: The objects being accessed can only be acquired below hand level, forcing the operator to flex their wrist (e.g. reaching into a part bin for a screw)

Solution: Eliminate barriers that obstruct the wrist, and/or ensure the surface is high enough to avoid wrist flexion. Examples of this include cut-outs in part bins, and adjustable height work surfaces.

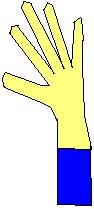

WRIST EXTENSION

Problem: The objects being accessed can only be acquired above hand level, forcing the operator to extend their wrist (e.g. typing on an improperly adjusted keyboard). This awkward posture is also caused by pushing objects that lack proper handles, forcing operators to put their wrists into extension to apply the maximum possible force, and by tool handles that are inappropriate for the surface being worked on.

Solution: Adjust work surfaces so that objects can be accessed with the wrist in neutral position. Ensure carts and other frequently pushed items have handles affixed to them. Use tool with pistol-grip handles for vertical surfaces, and inline handles for horizontal ones.

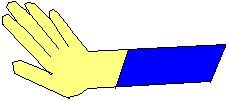

WRIST SIDE-DEVIATION

Problem: The objects that are being accessed are off-centre of the hands, forcing the operator to side-bend their wrists. Wrist side-bending is also performed when tearing receipts from cash registers, putting stress on the wrist over time.

Solution: Ensure work object is presented in front of the operator before aquiring it. If the speed of a conveyor causes the operator to perform this awkward posture, slow the conveyor, reduce the flow, or enable the operator to stop their section of the conveyor if the workload gets too heavy. As for tearing register receipts, acquire cash registers with the auto-receipt cutter, eliminating the need for the operator to do the tearing task.